Precision CNC Machining Services | Top Quality

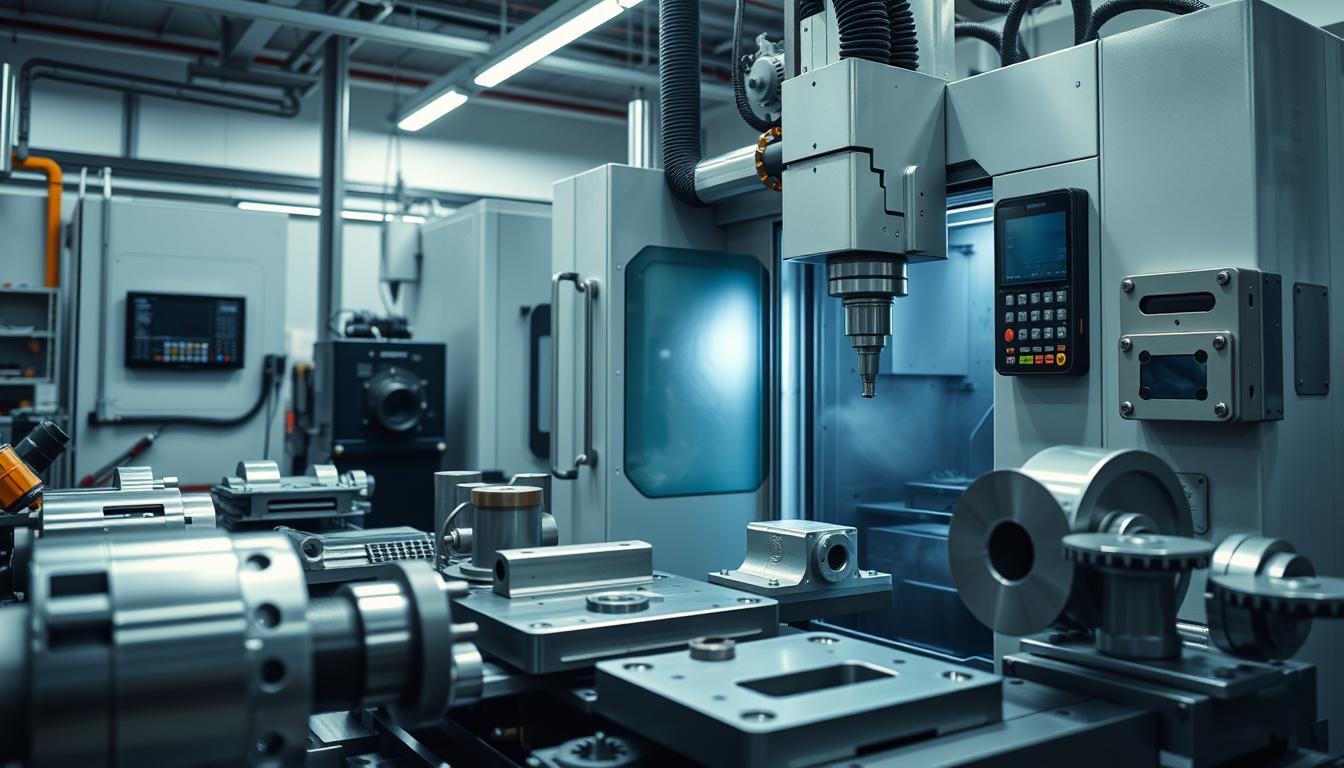

We lead in CNC machining services and promise excellence in every component we make. Our top-end technology and skilled team transform raw materials into precise parts. These meet the high standards of various industries like aerospace and medical. We guarantee superb quality with careful attention and strict quality control.

Key Takeaways

- State-of-the-art technology ensures precision in every component.

- Expert team dedicated to custom CNC machining solutions.

- Cater to various industries including aerospace and medical.

- Stringent quality control system for high-quality outputs.

- Commitment to delivering advanced manufacturing solutions.

What is CNC Machining?

Computer Numerical Control (CNC) machining marks a significant leap in how we make things. It uses computer software to direct machinery actions. Machines like grinders, lathes, mills, and routers move with outstanding precision thanks to it. This technology follows detailed instructions, boosting control, efficiency, and reliability in making intricate items.

Our precision engineering techniques ensure perfect execution of complex three-dimensional cuts in one attempt. CNC machining brings unmatched design accuracy and quality. It has revolutionized operations and spurred innovation across numerous industries.

Benefits of Precision CNC Machining

Precision CNC machining brings many benefits to manufacturing. This essential technology boosts quality, productivity, and controls costs. It’s key for many industries.

Accuracy and Precision

This machining process achieves high accuracy. Each piece is made with careful attention to detail. This ensures that every piece meets strict standards.

This level of precision is vital. In many fields, a small mistake can cause big problems. Thus, CNC machining’s accuracy is highly valued.

Efficiency and Speed

Automated machining stands out for its efficiency and speed. CNC machines quickly do complex tasks with precision. This cuts down on production time.

Thanks to this, companies can meet urgent deadlines. They boost productivity without losing quality.

Cost-Effectiveness

Precision CNC machining saves money too. It cuts down on waste and allows for mass production of quality parts. This is key in lowering production costs.

Automated efficiency means less spending and more profit. Businesses benefit greatly from this technology. It’s a win for their bottom line.

Materials Used in CNC Machining

CNC machining uses a wide range of machinable materials. This method is all about precision and flexibility when making top-notch parts. Metals and plastics are the main two types of materials. The unique material properties of each determine how the final product will work.

- Aluminum: It’s light and easy to shape, perfect for planes and cars.

- Brass: It’s great against corrosion and is conductive, fitting for electrical parts.

- Copper: Best for its conducting abilities, it’s a go-to for electronics and engineering.

- Steel: Known for toughness and flexibility, it’s used in many fields for strong builds.

- Titanium: Light yet strong and fights off corrosion, vital for medical and plane parts.

When it comes to plastics, here are the popular choices:

- ABS: This tough plastic is easy to work with, mainly used for making prototypes.

- Polycarbonate: Clear and resistant to impacts, it’s perfect where sturdy visuals are needed.

- PEEK: It stands up to chemicals and has top mechanical traits for engineering goods.

The choice of machinable materials is important. Their material properties greatly influence what the final piece can do and how long it lasts.

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, Excellent Machinability | Aerospace, Automotive |

| Brass | Corrosion Resistance, Electrical Conductivity | Electrical Components |

| Steel | Strength, Versatility | Construction, Machinery |

| ABS | Impact Resistance, Ease of Machining | Prototyping |

| Polycarbonate | Transparency, High Impact Strength | Visual Applications |

CNC Machining Services for Various Industries

Our CNC machining services cater to many industries, ensuring precision and quality. Industries like aerospace, automotive, and medical benefit greatly. Each component is crafted with care and precision.

Aerospace Industry

The aerospace sector demands high precision and reliability. Our services offer state-of-the-art components for aerospace needs. We use strong, lightweight materials ideal for harsh conditions. This ensures outstanding performance.

Automotive Industry

Our parts improve both performance and safety in the automotive world. We address various needs in automotive engineering. Our goal is to enhance efficiency and dependability with our CNC machining.

Medical Industry

Accuracy is vital in the medical sector. Our CNC machining produces devices that are precise and safe. We focus on medical device manufacturing, aiding healthcare providers in excellent care delivery.

| Industry | Key Focus | Benefits |

|---|---|---|

| Aerospace | Aerospace Components | Lightweight, durable, high-performance |

| Automotive | Automotive Engineering | Enhanced performance, reliability, safety |

| Medical | Medical Device Manufacturing | Accuracy, compliance, patient safety |

Understanding CNC Machining Techniques

In the world of CNC machining, we use different methods to create accurate and detailed parts. Some of these include milling, turning, drilling, and electrical discharge machining (EDM). Each technique has special benefits for making specific parts.

At the core of these advanced methods is CNC Programming. It changes creative ideas into real products. Good programming is key. It plans the machine’s movements to make sure everything is done right and efficiently.

Now, let’s look at some techniques more closely:

- Milling: This process removes material with rotating tools. It’s perfect for making complex shapes and fine details.

- Turning: This means spinning the piece while a fixed tool shapes it. It’s vital for making round parts.

- Drilling: This technique makes holes in the material. It’s important for many assembly tasks.

- EDM: This uses electrical shocks to mold tough metals. These metals are hard to work with using traditional ways.

We’re committed to using advanced machining methods to give clients the best results. With strong CNC Programming, we turn design ideas into precise, tangible products.

Choosing the Right CNC Machining Service Provider

When picking a CNC machining service, the right choice greatly affects your project’s quality and speed. A good CNC Provider combines experience, a commitment to quality, and the latest technology.

Experience and Expertise

Firstly, consider the provider’s experience and expertise. A Quality Machine Shop with a strong industry presence shows skill and reliability. Their history of successfully handling complex jobs shows they can deliver precise outcomes.

Quality Assurance

Quality assurance is key in selecting a provider. Look for those with clear quality control and industry compliance. A Trusted CNC Provider will have certifications and thorough testing methods. This ensures products meet top quality standards.

Technological Capabilities

A provider’s technology reflects their dedication to innovation and efficiency. Those who invest in Advanced CNC Technology achieve better results. Modern machines and software not only increase precision but also improve production speed. This makes for more timely deliveries and cost savings.

Custom CNC Machining Solutions

In the world of custom CNC machining, we offer precise and adaptable solutions. We recognize that every project is different. Thus, we provide tailored machining services for these unique needs.

We start with a thorough talk to understand our clients’ needs. Then, we work closely with them from the design to the final product. This ensures your custom fabricated parts fit perfectly. Our main goal is to go beyond your expectations.

Our approach to custom CNC machining is driven by a commitment to quality and precision, ensuring every component is crafted exactly as envisioned.

If your project needs a special part, specific industry needs or particular finish, we’re here to help. Our focus on customization lets us meet various demands with ease.

We handle every step of the machining process with great care. This ensures top quality and precision. Our expertise in tailored machining solutions makes us a dependable partner for your needs. We provide custom fabricated parts that fit right into your production.

In short, our custom CNC machining services aim to provide unique parts. These are made to match your precise requirements, ensuring top performance and satisfaction.

How to Optimize Design for CNC Machining

Making a design work for CNC machining is key. It helps achieve top-notch precision, efficient making, and great manufacturability. This process includes many important steps that help make the CNC machining work well.

Design Considerations

Creating designs for CNC machining means thinking about what the machine can do. You need to look at shape limits, keep designs simple, and plan how to hold the workpiece. These steps aid in getting the best out of machining and accuracy.

Material Selection

Picking the right material is crucial for a design that’s easy to make. Different materials offer varied machinability, strength, and cost. Aluminum, steel, and plastics are common choices. They affect the product’s performance and how much it costs.

Tolerance and Finish

The need for tight tolerances and specific finishes is a big part of CNC machining. More precise tolerances can raise costs and the time needed for machining. Also, the type of finish wanted can decide which tools and methods are used. Aiming for balance is key to get precision without overspending.

| Aspect | Considerations | Benefits |

|---|---|---|

| Design | Geometric limitations, complex features | Enhanced Machining Optimization |

| Material | Machinability, strength, cost | Optimal Design for Manufacturability |

| Tolerance and Finish | Tight tolerances, surface finish | Superior Precision Engineering |

Types of CNC Machines

CNC technology comes in different forms, each designed for specific manufacturing roles. You’ll find milling machines, turning centers, and multi-axis setups. These machines enhance how efficiently and accurately we make things.

Milling machines stand out by being very flexible. They work with a range of movements for complex shapes and designs. By spinning cutting tools, they remove material to create detailed and exact patterns.

Turning centers, or lathes, are best for symmetrical objects like rods and cylinders. They spin the material against a fixed cutting tool. This way, turning centers reliably make circular parts.

The multi-axis machining method takes CNC a step further. It works on multiple sides at once. This approach means less resetting and handwork for complex designs. From 3-axis to 5-axis, multi-axis machining adapts to challenging projects easily.