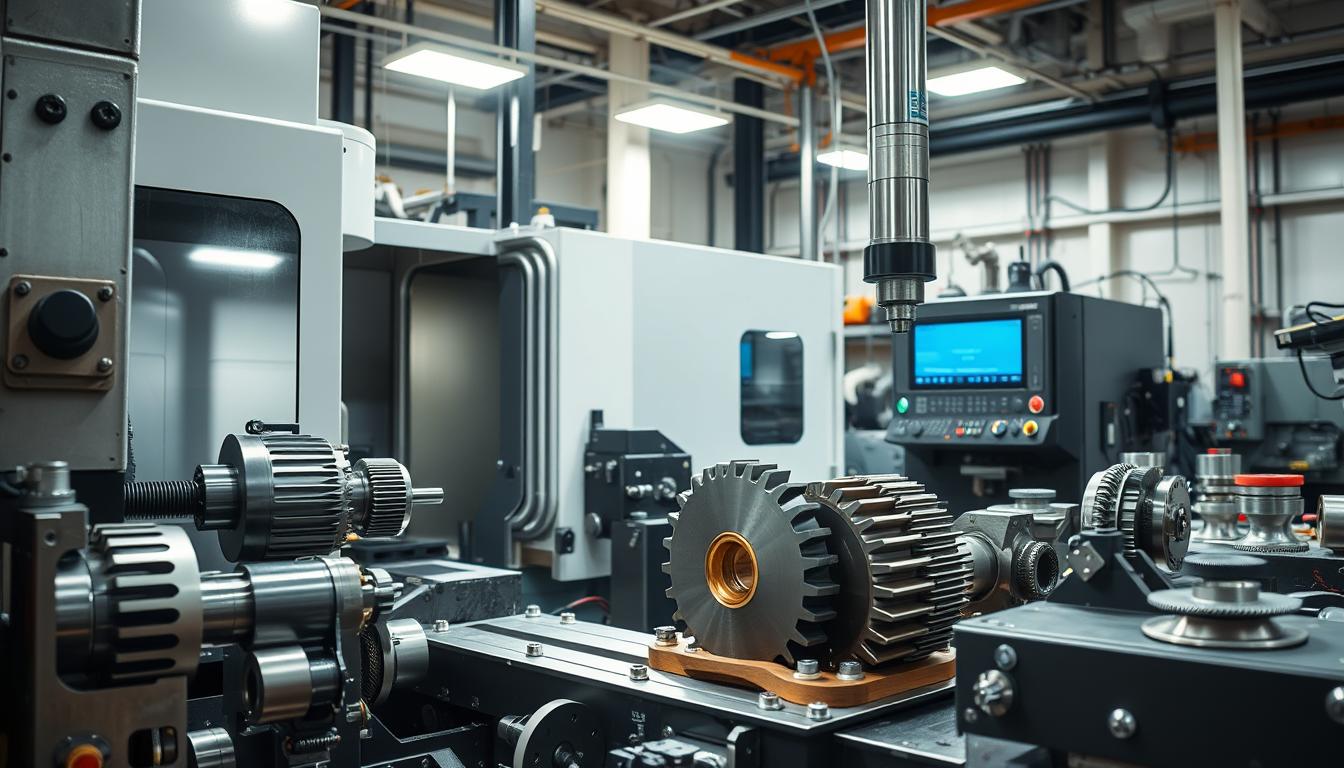

Precision CNC Machining Services in the USA

In today’s manufacturing world, Precision CNC Machining Services in the USA stand out. They offer custom machining that meets exact customer needs. Using advanced technologies and expert skills, they achieve amazing precision and efficiency. They make parts for many industries with great accuracy.

CNC Machining in the USA has really evolved. Companies like Modern Group lead with innovation, having over 25 years of experience. They use more than 50 CNC machines and 20 turning centers1. Their precision services can meet tight tolerances, up to +/- 0.002 in. (0.0508mm). They follow ISO standards for metal parts2.

Since 1980, The Federal Group USA has shown how CNC machining changes sectors. This includes aerospace and healthcare3. They use machines that can handle many materials. This includes copper and plastics, offering both precision and flexibility in making products31.

Key Takeaways

- Precision CNC Machining Services are instrumental in delivering customized solutions across various industries.

- Companies like The Federal Group USA and Modern Group are pivotal in advancing CNC machining capabilities in the USA.

- The services can achieve incredibly tight tolerances, adhering to international standards like ISO 2768.

- They are versatile with the ability to work with a wide variety of materials such as metals and plastics.

- Innovative machine tooling services ensure optimal precision and efficiency in manufacturing processes.

Introduction to CNC Machining Services

Today, CNC machining services play a crucial role in making things. They are used in industries like aerospace and automotive. These services help create parts with pinpoint accuracy. This is key to staying ahead in the fast-paced market of today.

Overview of CNC Machining

CNC machining stands for Computer Numeric Control machining. It’s a way to make things using computers to control machines, such as lathes and mills. This technology boosts how much can be made and ensures products are consistently high quality. It works by using software to direct how machines move, control speed, and change tools4.

This means parts can be made over and over with the same instructions. Conversational CNC programming also makes complex tasks like drilling easier. It’s as simple as using design software4.

History and Evolution

The story of CNC machining began in the late 1960s. It changed the manufacturing world by offering more control and faster production than old methods. Nowadays, CNC systems are even more powerful5. They include advanced features like high-pressure coolants and automatic tool changers. This has upped productivity and what CNC machines can do4.

Importance in Modern Manufacturing

In modern manufacturing, CNC machines are essential, especially for making metal and plastic parts5. Industries like aerospace and automotive depend on them for detailed components. Thanks to CAM programming, manufacturing complex parts has become smoother. This programming allows 3D models to set tool paths and machining processes4. Although CNC machining needs a bigger upfront investment, space, and special skills, its precision and adaptability make it vital for today’s manufacturing4.

Types of CNC Machines and Their Applications

Today, we have many CNC Machine Types, each fitting various industry needs. From simple to complex tasks, these machines offer solutions for numerous applications. They help in picking the right system based on specific requirements.

3-Axis Milling Machines

3-Axis CNC Milling Machines are straightforward but very functional. They work on three axes: x, y, and z. Known for their strong performance, they create parts with great accuracy.

They use cutting tools like end mills and drills6. Many sectors, including car making and health matters, depend on these machines7.

4-Axis Milling Machines

4-Axis CNC Milling Machines add an extra rotary axis, enhancing sculpting ability. They are key for working with complex shapes, making operations more efficient.

Used often in aerospace and medical equipment making, they do intricate work with ease7. The extra axis lets the material rotate, creating parts that are more complex than with a 3-axis machine.

5-Axis Milling Machines

5-Axis CNC Milling Machines are the top in CNC tech, moving parts along five axes at once. With x, y, z, and two more rotary axes, they make very complex shapes.

This leads to unmatched precision7. They excel in high-stake industries like aerospace and automotive, doing tasks more complex than 3-Axis and 4-Axis machines6. They’re key for making high-quality and intricate parts.

Industries That Benefit from Precision CNC Machining

Precision CNC machining is key for many industries, making parts with great detail and accuracy. This technology ensures products meet the highest quality standards. It’s used in different fields, always providing top-notch results.

Aerospace and Aircraft

The aerospace sector heavily relies on CNC technology to make complex parts with tight precision. CNC machines reach measurements as exact as ±0.0001”8. This ensures aircraft parts like turbine blades work perfectly, keeping flights safe.

This technique also allows for quick creation of bespoke parts. This meets the specific needs of cutting-edge aircraft designs, enhancing safety and efficiency in aerospace manufacturing9.

Medical, Dental, and Orthopedic

In healthcare, CNC technology is crucial for making precise medical tools and implants. It’s all about accuracy for patient safety and equipment effectiveness. The technology supports making everything from custom implants to MRI machines9.

Quick prototyping of these items ensures they work well before full-scale production. Making these parts in controlled environments is vital for critical medical devices9.

Automotive

In the auto industry, CNC machining allows for making prototypes and final parts with excellent design and function. Precision in making car parts ensures safety, performance, and compliance with laws. Customizing components quickly also speeds up design and reduces costs8.

This technique’s adaptability highlights its critical role in today’s manufacturing across different sectors.

The Precision and Accuracy of CNC Machining

Precision CNC machining offers top-notch accuracy for today’s manufacturing needs. It ensures little difference between actual and system measurements. This means parts meet strict quality standards10. CNC machining can achieve tolerances as close as ±0.01 mm. This is key for making parts that perfectly match every time11.

In the world of Precision CNC, tolerance means how much a measurement can differ from the standard. A machine with a ±0.05 mm tolerance has very small measurement variations11. This precision means parts fit together well, lowering errors in different uses.

| Precision Attribute | Description |

|---|---|

| CNC Accuracy | Difference between actual measurements and the system, indicating high precision10. |

| CNC Tolerances | Allowable deviation from the standard value, typically expressed in “+/-“10. |

| Repeatability | Capability to produce identical parts consistently with high precision11. |

Precision in CNC is also about making parts the same every time12. This requires good quality control. By focusing on accuracy and tolerances, parts made have minimal errors. They meet tough design and function needs.

Materials Commonly Used in CNC Machining

Picking the right materials is key in CNC machining, as it shapes the project’s success. The choices most often include metals, plastics, and composites. Each brings unique perks and strengths for different uses.

Metals

Metal CNC Machining uses various materials for their special features. Stainless steels like 304, 316, 416, and 17-4 PH are popular for fighting rust and being easy to shape13. Aluminum is liked for its lightness and strength, essential in fields like aerospace and cars13. Titanium shines with incredible strength and rust resistance, perfect for medical tools and space and military uses13.

Copper types, such as Copper 101 and 110, are prized for conducting electricity and heat well13. Brass, blending copper and zinc, works great for its easy shaping and rust resistance, used in plumbing and health devices13. Low carbon steel, like 1018, is affordable and simple to craft, fitting for motor parts13. Alloy steels 4130 and 4140 boost hardness and wear resistance, helping in home devices and cars13.

Plastics

Plastic CNC Machining is vital for light, adaptable uses. Favorites like HDPE, Nylon, PEEK, and Polycarbonate resist chemicals, electricity, moisture, and heat13. Their features make them perfect for long-lasting items in any setting, inside or out14.

Composites

Composites are chosen in CNC machining for demanding tasks needing high strength yet light weight. These materials excel in critical areas such as aerospace and automotive14. They also stand up to a lot of stress, making them great for complex manufacturing needs14.

Prototyping to Full-Scale Production with CNC Machining

CNC machining is key in taking an idea to a fully made product because of its accuracy and variety. It plays a crucial role from early prototypes to large-scale production. Let’s explore how CNC machining aids this journey, focusing on rapid prototyping and its ability to grow.

Rapid Prototyping

Making prototypes with CNC is a big help for manufacturers. It lets them create prototypes fast and with great detail. First, they make a 3D CAD model, which becomes CAM files that carry G Code. This makes sure the prototype exactly matches the design, using steps like milling, turning, and working on several axes at once15. This method works with many materials, including plastic and metal variants such as PS, LDPE, aluminum, and titanium15. Depending on what you’re working with and the machine used, the precision is very tight, ranging from 0.1 mm to 0.02 mm16.

Scalability and Flexibility

CNC’s true power is in how it can be scaled and adapted, essential for moving from a single prototype to mass production. This adaptability lets businesses change how much they make without losing quality. This way, they can grow while keeping products consistent and production efficient. CNC methods let makers respond to what the market wants quickly and affordably, skipping the high costs of traditional molds or dies16.

This approach also allows for making complex shapes, giving designers the freedom to be creative. Fast prototyping and production with CNC cuts down the time from design to final product. This keeps companies ahead in a competitive and quick-moving market16.

Overall, the path from CNC prototyping to mass production is smooth thanks to CNC machining’s benefits. It gives scalable solutions that offer precise and efficient results at every step. This makes it a fundamental part of modern manufacturing.

Top CNC Machining Companies in the USA

The United States is a leader in the CNC machining market. It’s known for top companies that greatly improve the field. They are celebrated for their accuracy, innovative methods, and dependability.

Protolabs

Since 1999, Protolabs has been a major player in CNC machining. They began offering these services in the late 2000s, adding to their plastic injection molding17. Protolabs shines in quick prototyping and manufacturing. They use advanced CNC tech and automated checking to ensure products are top-notch and arrive fast18. This company is a key figure among top CNC firms in the USA.

TDL Mould

TDL Mould was started in 1995. They are experts in making both plastic and metal parts fast and with extreme care17. They have the latest 5-axis CNC machines and many high-speed machines. TDL Mould is known for its dedication to precision and reliability in its CNC work18. They are a top choice in the CNC industry in the USA.

Titan America MFG

Titan America MFG began in 2005. They’re known for their precise machining for tough sectors like aerospace and medical17. They use state-of-the-art machining methods to make complex parts that meet high-quality standards18. Titan America MFG shows how top CNC companies in the USA adapt to changing manufacturing demands, maintaining high performance.

Advantages of Precision CNC Machining

Precision CNC machining brings many advantages to manufacturing in all sorts of fields. It makes the production flow better and increases efficiency, all while saving costs. These benefits are key for CNC machining’s popularity.

Improved Workflow and Efficiency

CNC machining boosts the speed and smoothness of production. It supports many materials, like metals and plastics, making it easier to move from one step to another19. This technique can create very precise parts due to its tight tolerance levels. It ensures all parts are the same, cutting down mistakes19. Also, by doing several steps at once, CNC machines make things more efficient and speed up the work in shops20.

Another plus is that CNC machines can work all day and night. This means they can keep making parts without stopping, which boosts CNC efficiency19. With the machines running nonstop, companies can meet large orders quickly. Plus, fewer workers are needed, saving money on labor costs20.

Cost-Effectiveness

CNC machining is known for being cost-effective. It cuts down on waste by machining parts exactly right, so less material is thrown away20. This process guarantees top-quality output every time because it uses steady speeds and feeds20.

It also saves on the cost of manpower and training. With its high efficiency and few mistakes, CNC machining lowers the cost of making things19.

CNC machining makes workshops safer too. With its enclosed spaces, workers are protected from dangers, leading to fewer accidents19. This safety measure helps keep production up without unnecessary breaks.

How to Start a CNC Machining Project

Starting a CNC machining project is all about planning well to meet clients’ needs and ensuring top-notch results. We will go through important steps from the first meeting to making sure everything is made just right, highlighting key things for a successful project.

Initial Consultation

The journey starts with an initial consultation. In this step, the client and the CNC service provider talk about what the project needs. They make sure the service fits the client’s goals, covering everything from what materials to use to the complexity of the design. They also talk about costs, which are usually between $120 to $16021.

Design and Prototyping

After talking it over, it’s time for the design and making a prototype. They use advanced CAD software, like Fusion 360, which works on Mac and PC. This software is key for building perfect digital models22. Fusion 360 also helps with making 3D surfaces and CNC machining. Making a prototype first means they can catch any mistakes before making a lot of them, saving money and time.

Production and Quality Control

With the design and prototype okayed, production starts. Keeping an eye on quality control in CNC is crucial to keep things top-quality. They mark up the cost of raw materials by 20 to 35 percent and charge $60 to $150 per hour for machining21. Checking quality at every step makes sure everything is as it should be, reducing the need to redo things. Also, work done after the machining usually adds 20 to 35 percent more to the cost21, so careful quality checks help avoid extra expenses.

By sticking to these steps, companies can start and finish CNC machining projects well. This ensures the work is precise, high-quality, and makes clients happy, from start to finish.

Conclusion

CNC machining marks a major leap in how things are made today. It brings unmatched efficiency and exactness to creating parts. Objects like bushings and collars, along with components for airplanes and medical devices, are made quickly and precisely. This process keeps production smooth and fast23.

It plays a key role in the success of many industries, such as aerospace, cars, and healthcare. CNC machining is flexible, moving easily from making prototypes to bulk items. With advanced software, makers can craft parts with incredible detail and accuracy24.

More than a simple tool, CNC machining is a game-changing method that combines speed with accuracy, all while being cost-effective. It works with a variety of materials, including metals and composites. This makes it a core part of ongoing industrial innovation. CNC machining is leading the way, promising exciting changes in how we produce things in the future25.