CNC Machining Services | Quick Turnaround

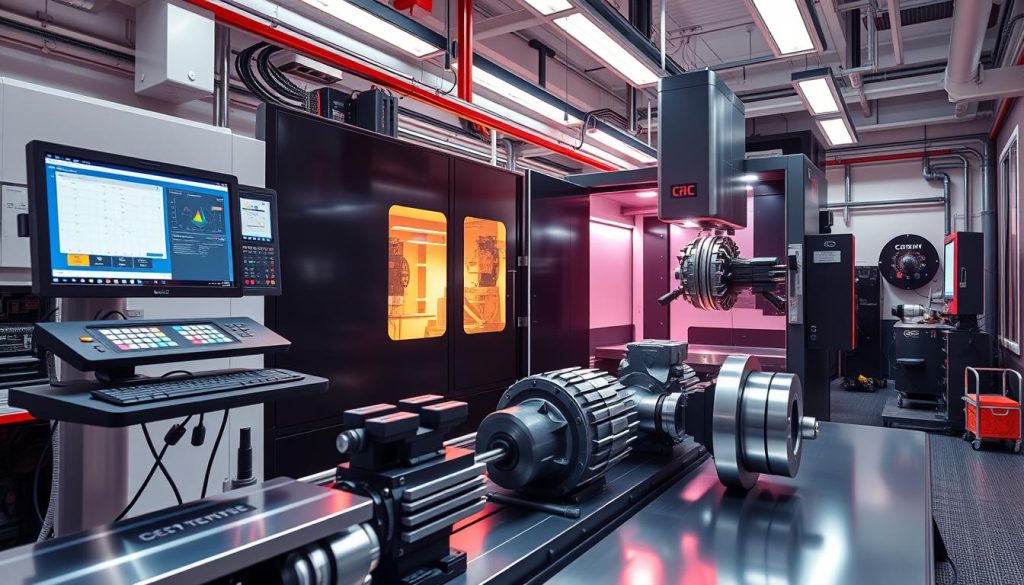

We are at the forefront of innovation, offering precision CNC services. Our services meet the dynamic needs of today’s industries. Known for rapid prototyping and quick-turn machining, we focus on creating specific solutions with custom CNC parts. We ensure fast manufacturing without compromising on our quality workmanship.

Our facility is recognized for excellence, holding ISO 9001:2015, AS9100D, and ITAR Registrations. We work with a variety of materials, including Aluminum, Titanium, ABS, and Nylon. Our team is ready for any project, capable of making parts up to 22 in. x 14 in. x 3.75 in. with precision within +/- 0.005 in.

With our large U.S.-based facility and advanced equipment, we promise little to no downtime and quick service. This approach changes the speed expectation in CNC machining. We can deliver parts in just 1 day.

Key Takeaways

- Provision of precision CNC services for complex, high-quality manufacturing needs.

- Capability to realize rapid prototyping and quick-turn machining, responding effectively to tight project timelines.

- Availability of custom CNC parts in a vast array of materials, with turnaround times as little as 1 day.

- Upholding rigorous standards with comprehensive certifications such as ISO 9001:2015, AS9100D.

- Mastery of expedited manufacturing solutions, employing advanced machinery and skilled craft to exceed expectations.

CNC Machining vs. Traditional Machining

Manufacturing technology has changed a lot, making CNC machining and traditional machining more distinct. Each has unique benefits in the industry. Knowing these differences helps manufacturers pick the best production methods. They aim for quality, efficiency, and saving costs.

The Evolution from Manual to Automated Machining

Automated machining has truly changed how things are made. It moved from manual work to advanced CNC systems. This change is due to new technology. It lets us control machining processes precisely. Now, we can turn digital designs into real objects with little need for people.

Precision and Accuracy in Modern CNC Machining

Today’s CNC machines are very advanced, allowing for precise work. Before, it all depended on the worker’s skill. But now, CNC adds to that skill. This ensures uniform, high-quality products even in large amounts.

Significance of Computer Numerical Control in Manufacturing

CNC plays a huge role in modern manufacturing. It lets us make complex designs efficiently and consistently. This is a big step up from older methods, especially for making lots of things at once.

| Aspect | Traditional Machining | CNC Machining |

|---|---|---|

| Cost-effectiveness (Small Jobs) | Higher | Lower |

| Complexity Handling | Limited | High (up to 6 processing axes) |

| Part Consistency | Varies by operator skill | High consistency and repeatability |

| Production Volume | Low volume efficiency | Highly efficient for large volumes |

| Flexibility in Scaling Production | Limited | High |

| Operator Involvement | High | Minimal, with potential for automation |

| Precision | Lower | High, typically 0.0002 to 0.0005 inches |

| Setup Time and Cost | Lower for small runs | High, suited for long-term projects |

Switching to CNC machining is a big deal in making things today. It’s all about wanting more accuracy and efficiency. And tackling complex tasks easier. Using CNC technology helps companies do better in a tough market.

Understanding the CNC Process and Its Efficiency

The journey from a digital design to a precise part shows how far CNC has come. This change is rooted in an automated manufacturing process. It cleverly turns raw materials into critical components for many fields.

From Digital Design to Physical Part: The CNC Workflow

The CNC process starts with a precise digital design, often a CAD model. It’s then turned into machine instructions through CAM software. This shows how technology and manufacturing skillfully come together.

The main steps include:

- Design Input: Getting the initial idea or CAD drawing.

- Programming: Changing the design into a format the machine can read.

- Setup: Getting the CNC machine ready with the right tools and materials.

- Machining: Actually cutting, milling, or turning the material.

- Inspection and Quality Control: Making sure the part meets all requirements.

Capabilities of CNC Machinery: What CNC Can Accomplish

CNC machines are not just for certain jobs. They are powerful tools that excel in many manufacturing tasks, from prototypes to full-scale projects. These abilities include:

- High Precision and Consistency: Machines make parts with tight tolerances. This ensures uniformity across many items.

- Complex Shape Production: CNC can create intricate three-dimensional shapes. Such shapes would be nearly impossible to make by hand.

- Material Versatility: CNC works with many materials, including metals, plastics, and composites. This offers flexibility in what you can make.

- Speed and Efficiency: Fast production and fewer mistakes mean more efficiency. This makes CNC machining cost-effective.

Understanding CNC’s workflow and abilities improves production and sparks innovation. It expands what’s possible in modern manufacturing.

CNC Machining Services for Various Industries

We specialize in custom CNC manufacturing for many sectors. Our precision parts meet the needs of different industries. We use advanced technology and years of experience in every project.

We’re proud to work with aerospace, electronics, and more. Our expertise shows our ability to adapt. We can tailor custom CNC manufacturing solutions to meet specific needs.

| Industry | Material | Example Part | Price |

|---|---|---|---|

| Aerospace | Aluminum 7075-T6 | Circuit casing | €275.10 |

| Industrial Automation | Aluminum 6061-T6 | Control console | €83.50 |

| Research | Aluminum 6082 | Lab equipment frame | €299.17 |

| Electronics | Aluminum 6063 | Chassis for devices | €61.15 |

| Academia | PEEK | Research components | €137.61 / €212.42 |

Our facilities have over 65,000 square feet for CNC machining. We meet high standards for CNC precision parts. Our facilities include many milling and turning centers, making our capabilities top-notch.

Baker Industries has over 30 years in CNC machining. Our skilled team uses the latest CNC technology. We are leaders in diverse industry applications.

If you’re new to our services, there’s good news. We offer a 20% discount on custom parts up to $1,000/€1,000. This deal lasts until November 30, 2024. It shows our commitment to quality and precision. These are key to our services that meet tough industry standards.

Materials Compatibility in CNC Machining

Our CNC services focus on material compatibility and customizing metal and plastic machining. This ensures top performance for each use. We carefully pick the best engineering-grade materials. This balances technical needs and practical uses.

Metals and Plastics Utilized in CNC Services

We offer a wide variety of materials for CNC machining, from strong metals to flexible plastics. Each type meets different needs and can handle certain conditions. For example, aluminum grades like 6061 and 7075 are strong yet lightweight. They’re perfect for the aerospace and auto industries.

Stainless steel types such as 304 and 316 are used where corrosion resistance is key. This is important in medicine and marine use. Similarly, plastics like ABS, nylon, and polycarbonate are durable and easy to work with. They’re great for consumer products and car parts.

Specialty Materials and Requests in CNC Production

Some projects need materials with unique properties, like extreme temperature resistance. We offer both plastic and metal CNC machining for these cases. Titanium and Inconel are known for their strength and ability to withstand heat. They’re chosen for aerospace and military projects.

We also find rare materials like fiber epoxy and Garolite via our digital network. This meets very specific project needs. Knowing material details such as tensile strength and resistance to wear is important. Titanium, for instance, is good for medical use because it’s biocompatible and resists corrosion.

Plastics like PEEK are used in the chemical industry for their thermal stability and resistance to chemicals. We make sure to choose materials that perfectly match the requirements of your project. This careful matching ensures materials work well for their intended applications.

In summary, using the right engineering-grade materials enhances the performance and life of CNC machined parts. We pair material features with your project’s demands. This guarantees the best fit and performance. Our precision and reliability in CNC machining solutions stand out.

The Advantages of Quick-Turn CNC Fabrication

In manufacturing, being quick to update and improve product designs is crucial. Quick-turn CNC prototyping lets companies match the fast pace of product development and changing market needs.

Quick-turn CNC fabrication is more than a process; it’s a key advantage. It enables companies to quickly adapt to new trends and feedback. The use of advanced CNC technology cuts down the time from design to production, boosting both efficiency and flexibility.

Speedy Prototyping and Iteration with CNC Services

Turning ideas into physical prototypes is easier than ever. With quick-turn CNC prototyping, you can make prototypes quickly for testing and review. This speed in making changes is essential for fixing and finalizing designs before mass production, cutting down the product development time and speeding up time to market.

Meeting Tight Deadlines with Rapid CNC Manufacturing

Fast CNC manufacturing is key to keeping up with strict deadlines while ensuring product quality. By using the precise and fast CNC machining, products are made quicker. This helps stick to project schedules and meet client expectations, especially in sectors where speed affects market success and earnings.

| Feature | Traditional Machining | Quick-Turn CNC Machining |

|---|---|---|

| Energy Efficiency | Lower | Higher, uses about 1/7th energy (EPA) |

| Production Speed | Slower | Significantly faster, up to 60% faster with providers like Fictiv |

| Cost Effectiveness | Less cost-effective | More cost-effective, minimizes errors and waste |

| Safety | Higher risks | Lower risks, automated processes |

| Lead Time | Up to 22 weeks | Reduces to as few as 3 weeks (Honeywell case with Fictiv) |

| Material Versatility | Limited | Extensive, including metals, plastics, glass, wood |

The table shows that quick-turn CNC prototyping and fast CNC production are better than older methods in several ways. They are faster, use less energy, and are safer. These improvements are vital in industries like aerospace and medical devices, where high precision and reliability are crucial.

By adopting rapid CNC methods, businesses can keep up in a constantly changing market. This approach ensures they stay leading in innovation. It allows the delivery of top-quality, precisely engineered products quickly.

CNC Machining Applications Across Sectors

CNC machining is at the core of innovation in many industries. It plays a key role in making essential components with great precision. The technology helps create everything from CNC aerospace components to medical device machining. This shows how flexible it is to meet needs in different sectors.

Aerospace, Automotive, and Beyond: CNC’s Versatility

In aerospace, CNC machines are vital for making parts like airfoils and landing gear. These parts have to meet strict safety and quality rules. For automotive part manufacturing, CNC is used to make important parts. These include gearboxes and engine components that are crucial for cars and performance vehicles.

Custom Machining for Technology and Healthcare Innovations

In healthcare, CNC machining’s precision is a must-have. It is used to make complex medical devices like bone screws and surgical tools. Safety for patients and successful treatments depend on this high level of accuracy. This ensures even the most specialized medical devices are made perfectly.

Sectors like marine, defense, and energy also benefit from CNC tech. Parts such as hull structures, missile components, and turbine blades are made to meet exact needs. Below is a comparison of how CNC machining aids various industries:

| Industry | Applications | Specific CNC Uses |

|---|---|---|

| Aerospace | Engine components, landing gear, manifolds | Machining of aluminum, titanium, and advanced composites |

| Automotive | Engine parts, suspension components, body parts | Milling and lathing of metals and plastics |

| Healthcare | Orthopedic implants, surgical tools | Precision machining of stainless steel and titanium |

| Electronics | Circuit boards, enclosures, RF components | Fabrication of detailed electronic parts and insulators |

| Energy | Turbine blades, solar panel frames | Manufacturing of durable and weather-resistant components |

| Marine | Hull pieces, engine components, propellers | Creation of corrosion-resistant parts for marine environments |

Investing in CNC technology meets the complex needs of various sectors. It drives our commitment to precise, efficient, and reliable manufacturing. Every component we make shows our skill in meeting the needs and changes in industries.

Enhancing CNC Parts Through Post-Processing

At the heart of making CNC machined parts better, we focus on their function and look. Our top-notch process boosts the surface finish and meets specific industry needs.

CNC post-processing uses various techniques to make parts perform and last longer. We offer anodizing, powder coating, and chromate coatings. These processes help pieces stand out in quality. They are crucial for industries like aerospace and automotive that need toughness and precision.

- Anodizing adds a corrosion-resistant layer and can be done in various colors to enhance visual appeal and functionality.

- Powder coating provides a thick protective layer that shields against impact and corrosion.

- Chromate coatings offer excellent corrosion resistance without compromising the conductivity of the part.

Our machined part enhancements come with the best quality control. We use coordinate measuring machines and thorough optical inspections. Every process meets NADCAP and NABL standards, ensuring top-notch quality.

Understanding the need for fast delivery, we offer quick surface finish processes. Our team has a 95.4% on-time delivery rate, serving over 3,000 companies. We are proud to provide fast, premium CNC machining and post-processing services. Here’s what our enhanced CNC parts offer:

| Material | Finishing Option | Lead Time |

|---|---|---|

| Aluminum 6061/6082, 7075 | Anodizing, Chromate Plating | As fast as 4 days |

| ABS, Brass, Bronze, Copper | Powder Coating, Bead Blast | 3 to 10 days |

| Stainless Steel, Titanium | Electropolishing, Passivation | 7 to 10 days |

With our personalized CNC post-processing for different materials, we make sure your parts are perfect. They will be more durable and look better, ready for any use.

Designing for CNC: Best Practices for Cost Management

We explore how to optimize CNC machining designs for lower costs. We’ll share strategies to improve the design while reducing expenses. This boosts both manufacturability and quality.

- Optimize Machining Time: We aim to simplify designs to cut down machining time and costs, especially for large orders.

- Smart Material Selection: Choosing easy-to-machine, less expensive materials helps lower costs. Using standard sizes also cuts waste.

- Minimize Complex Geometries: Simpler designs mean fewer setups in machining, lowering costs and avoiding unnecessary part complexity.

We suggest design changes to make manufacturing easier:

- Keep cavity depth within four times its length to ease machining and cut costs.

- Design with thicker walls to enhance stability, reducing machining time and chatter.

- Choose standard drill sizes for holes and limit the use of unusual sizes that increase costs.

| Design Feature | Recommendation | Cost Impact |

|---|---|---|

| Cavities | Depth not exceeding four times the width | Reduces machining difficulty and time |

| Thread Length | Maximum of three times hole diameter | Limits material and tooling costs |

| Tolerances | Specify only where necessary | Decreases processing and inspection time |

Our goal is to enhance manufacturing efficiency and cost management through these CNC design optimizations.

We also use advanced tech and batch production to save costs. This lets us offer high-quality, cost-effective CNC services that meet client needs precisely.

Skilled labor is key in CNC machining. We wisely manage this resource to control production costs while ensuring top quality. This balance is crucial for our success in the competitive CNC market.

In summary, optimizing CNC designs is vital for reducing manufacturing costs. Let us help you achieve cost-effective production without compromising on quality.

Precision and Tolerances in CNC Machined Parts

In CNC machining, precision machining standards and CNC part tolerances are key to quality. They are vital in fields like aerospace, medical, and automotive. Even a small mistake can cause big problems. Our goal is to make sure every part meets tough intricate CNC manufacturing standards and our clients’ needs.

We are proud of our precision in all sorts of materials and designs. This leads to strong and reliable final products. The table below shows the tolerances we aim for. This reflects our promise of top-notch quality through advanced CNC machining.

| Tolerance Type | Specification | Applicable Material | Industry Application |

|---|---|---|---|

| Bilateral | +/-0.05mm | Metal alloys, Plastics | Aerospace, Medical |

| Unilateral | +0.00/-0.07mm | Hardened Metals | Defense, Automotive |

| Geometrical (GD&T) | As per ISO 2768 | Composite Materials | Consumer Electronics |

| Limit | 19.996-20.005mm | Stainless Steel | Energy, Utilities |

We pick machining tolerance types like standard, bilateral, and unilateral carefully. We consider material traits and part needs. For example, stainless steel and hardened metals need strict tolerances for critical use.

To hit high CNC part tolerances, we blend skill with the newest CNC tech. This boosts efficiency and keeps us true to precision machining standards. It works for all projects, no matter how complex.

We get how these factors work together. This lets us manage intricate CNC manufacturing well. Every part fits just right and works as needed in important settings. Through testing and quality checks, we make sure our CNC parts meet all expectations and rules.

To sum up, by focusing on precision and tight tolerances, we stay dedicated to excellent CNC machining. This keeps our place as leaders in making quality, reliable parts.

Machining Capacity and Infrastructure at the Forefront

Our operation’s heart features high-capacity CNC machining. This capability speeds up production across many industries. We have a broad setup with cutting-edge manufacturing technology. This setup can tackle everything from small custom pieces to big production batches, both fast and well.

Maximizing Output with Advanced CNC Machine Shops

We use over a thousand advanced CNC machines at the heart of our strategy. These machines make us a top-notch CNC machining center with very high output rates. Our wide range of machinery meets many needs. From the precise work needed for medical devices to tough parts for the defense industry, we cover it all. Plus, our New Jersey location near big logistic centers improves our delivery speeds.

Capacity Planning for Scalable Manufacturing Solutions

Our setup is ready to scale up or down as our clients require. Our CNC solutions are flexible. They adapt to changing demands without losing quality or causing delays. This adaptability is crucial for fields like aerospace and automotive, where production needs can shift a lot.

We go beyond having the right machines. We invest in training our staff and keeping strong ties with suppliers. This approach helps us avoid problems like worker shortages and supply chain issues. It makes sure we always have the materials and parts we need.

To show how our CNC skills help different industries, look at this table:

| Industry Sector | Benefits of Our CNC Machining |

|---|---|

| Aerospace | Precision engineering for prototypes and regular production, enhancing aerodynamics and safety. |

| Automotive | Custom manufacturing of critical components like pistons and brake discs with strict adherence to specifications. |

| Medical Devices | Consistent output quality, crucial for high-volume production of intricate designs such as surgical tools. |

| Electronics | Miniaturized component production with the high precision needed for today’s compact electronic devices. |

| Marine | Efficient production of uniformity in parts needed for marine operations, under stringent conditions. |

| Oil & Gas | Durable components capable of withstanding harsh environments. |

| Defense | Robust and precise component fabrication that meets the highest standards of durability and reliability. |

| Consumer Goods | Flexibility to produce both small bespoke items and large-scale product runs, quickly adapting to market trends. |

Choosing the Right CNC Service Provider

Choosing a reliable CNC provider is vital for precision manufacturing. In the competitive world of modern manufacturing, having a trusted CNC machining partner boosts your efficiency and product quality. We stand out as a leader in the industry, with deep knowledge of CNC project needs. Our expertise goes beyond basic machining.

Our work spans industries like aerospace and medical technology. This has sharpened our skills in meeting high standards for quality and precision. Known for expert CNC services, we are committed to top-notch quality. This commitment shows in our strict quality control, speedy completion times, and our ability to adapt quickly. Our facilities boast diverse CNC machines and are ISO 9001 certified, ensuring our high standards. Plus, our strategic locations help cut shipping costs and improve communication. This meets the urgent needs of businesses with efficiency and precision.

We understand each company has unique needs. So, we customize our services for you, offering flexibility in materials and processes. Our size and scalability mean we can handle your projects now and adjust as your needs change in the future. We take data security seriously to protect your intellectual property. Our team’s skill shines in our projects and our continuous improvement efforts. Choosing us means choosing a partner who cares about fast prototyping, production, and exceptional customer service. It’s about investing in a partnership for mutual success.